Multi Fuel Engine:-

The main aim of our project is to run a two stock engine

from multi fuel.

i.e

1. LPG

2.Petrol

Fuel are always not available , so that we use multi fuel

engine, because we have multi fuel option to run a engine. In US army all the

vehicles are multi fuel engine.

The two-stroke engine consists of only three mobile parts:

Piston, connecting rod and crankshaft.The first two-stroke engine was a gas

engine invented and built by Etienne

Lenoir in 1860. A

two-stroke diesel engine was built by Dugald

Clark in 1878

A

multifuel engine is constructed so that its compression ratio permits firing the highest octane fuel of the various accepted

alternative fuels. A strengthening of the engine is necessary in order to meet

these higher demands. Multifuel engines sometimes have switch settings that are

set manually to take different octanes, or types, of fuel.

The Parts Required for Multi Fuel Engine are:-

1.

2 Stock Eninge

2.

LPG

3.

Petrol

4.

Vapourizor Kit

5.

Stand

6.

Pipes

7.

Petrol Container

8.

Regulator

9.

Cylinder

10.

Swiths

Mode of operation of the Two-Stroke engine

1st Stroke

At the point where the spark plug fires, fuel and air in the cylinder have been compressed, and when the spark plug fires the mixture ignites.

The resulting forces drives the piston downward. As the piston moves downward, it is compressing the air/fuel mixture in the crankcase.

As the piston approaches the bottom of its stroke, the exhaust port is uncovered. The pressure in the cylinder drives most of the exhaust gases (but not all) out of cylinder.

As the piston finally bottoms out, the intake port is uncovered. The piston's movement has pressurized the mixture in the crankcase, so it rushes into the cylinder, displacing the remaining exhaust gases and filling the cylinder with a fresh charge of fuel.

2nd stroke

Now the momentum in the crankshaft starts driving the piston back toward the spark plug for the compression stroke.

As the air/fuel mixture in the piston is compressed, a vacuum is created in the crankcase. This vacuum opens the reed valve and sucks air/fuel/oil in from the carburetor. Once the piston makes it to the end of the compression stroke, the spark plug fires again to repeat the cycle.

There is a third

type of engine, known as a two-stroke engine, that is commonly

found in lower-power applications. Some of the devices that might have a

two-stroke engine include:

·

Dirt

bikes

·

Mopeds

·

Jet

skis

·

Small

outboard motors

In this article,

you'll learn all about the two-stroke engine: how it works, why it might be

used and what makes it different from regular car and diesel engines.

Two-stroke Basics

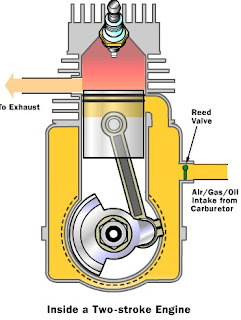

This is what a

two-stroke engine looks like:

You find

two-stroke engines in such devices as chain saws and jet skis because two-stroke engines

have three important advantages over four-stroke engines:

·

Two-stroke

engines do not have valves, which simplifies their construction and lowers

their weight.

·

Two-stroke

engines fire once every revolution, while four-stroke engines fire once every

other revolution. This gives two-stroke engines a significant power boost.

·

Two-stroke

engines can work in any orientation, which can be important in something like a

chainsaw. A standard four-stroke engine may have problems with oil flow unless

it is upright, and solving this problem can add complexity to the engine.

These advantages

make two-stroke engines lighter, simpler and less expensive to manufacture.

Two-stroke engines also have the potential to pack about twice the power into

the same space because there are twice as many power strokes per revolution.

The combination of light weight and twice the power gives two-stroke engines a

great power-to-weight ratio compared to many four-stroke

engine designs.

You don't normally

see two-stroke engines in cars, however. That's because two-stroke engines have

a couple of significant disadvantages that will make more sense once we look at

how it operates.

The Two-stroke Cycle

The following

animation shows a two-stroke engine in action. You can compare this animation

to the animations in the car engine and diesel engine articles to see the differences. The

biggest difference to notice when comparing figures is that the spark-plug

fires once every revolution in a two-stroke engine.

This figure shows

a typical cross flow design. You can see that two-stroke

engines are ingenious little devices that overlap operations in order to reduce

the part count.

Sparks Fly

You can understand a two-stroke engine by

watching each part of the cycle. Start with the point where thespark

plug fires. Fuel

and air in the cylinder have been compressed, and when the spark plug fires the

mixture ignites. The resulting explosiondrives

the piston downward. Note that as the piston

moves downward, it is compressing the air/fuel mixture in the crankcase. As the

piston approaches the bottom of its stroke, the exhaust port is uncovered. Thepressure in the cylinder drives most of the

exhaust gases out of cylinder, as shown here:

The Compression

Stroke

Now the momentum

in the crankshaft starts driving the piston back toward the spark plug for thecompression

stroke. As the air/fuel mixture in the piston is compressed, a vacuum is

created in the crankcase. This vacuum opens the reed valve and

sucks air/fuel/oil in from the carburetor.

Once the piston

makes it to the end of the compression stroke, the spark plug fires again to

repeat the cycle. It's called a two-stoke engine because there is a compression

stroke and then a combustion stroke. In a four-stroke

engine, there are separate intake, compression, combustion and exhaust strokes.

You can see that

the piston is really doing three different things in a two-stroke engine:

·

On

one side of the piston is the combustion chamber, where the piston

is compressing the air/fuel mixture and capturing the energy released by the

ignition of the fuel.

·

On

the other side of the piston is the crankcase, where the piston is

creating a vacuum to suck in air/fuel from the carburetor through the reed

valve and then pressurizing the crankcase so that air/fuel is forced into the

combustion chamber.

·

Meanwhile,

the sides of the piston are acting like valves, covering and

uncovering the intake and exhaust ports drilled into the side of the cylinder

wall.

It's really pretty

neat to see the piston doing so many different things! That's what makes

two-stroke engines so simple and lightweight.

If you have ever

used a two-stroke engine, you know that you have to mix special two-stroke

oil in with the gasoline. Now that you understand the two-stroke cycle

you can see why. In a four-stroke engine, the crankcase is completely separate

from the combustion chamber, so you can fill the crankcase with heavy oil to

lubricate the crankshaft bearings, the bearings on either end of the piston's

connecting rod and the cylinder wall. In a two-stroke engine, on the other

hand, the crankcase is serving as a pressurization chamber to

force air/fuel into the cylinder, so it can't hold a thick oil. Instead, you

mix oil in with the gas to lubricate the crankshaft, connecting rod and

cylinder walls. If you forget to mix in the oil, the engine isn't going to last

very long!

No comments:

Post a Comment